Sustainability, ›circular fashion‹, digitization and mass customization – the fashion industry is transforming at a fast pace. Designers seek for new production methods and partnerships that offer shorter communication and distribution channels to meet the market demands and gain more transparency.

Accelerating this development, International Design Center Berlin launched a networking program to connect Berlin-based fashion designers with Polish manufacturing and service providers. The program which will be continued with a B2B event at Kunstgewerbemuseum on October 26 to 27 has already led to a series of successful cooperations.

What are the benefits and challenges for a production in Europe? How to keep up with the current trends and market changes? Marte Hentschel, founder & CEO of fashion network Sourcebook spoke with Marita Jablonski (Good Garment Collective), Victor Koshevsky (Dynalian and Poge Industries), Julia Leifert (Philomena Zanetti) and Grzegorz Słupianek (Art Dress) about their experiences and the future of fashion design and production.

Marita, your agency ›Good Garment Collective‹ has a lot of experience collaborating with manufacturers in Poland. From your perspective, what are the opportunities and challenges of cross-border collaborations in the fashion industry?

Marita Jablonski: One of the huge advantages of working with Polish companies compared to Far East productions is the short distance. You can speed up production processes and gain flexibility because of the short communication channels. Language barriers are still a challenge for the cross-border production. With Greg or Victor we can speak German, but not everyone within the company will speak English or German. So there are some translation issues and limits to whom you will be able to talk.

Julia, your fashion collection is produced sustainably. What are you looking for when you choose your production partners?

Julia Leifert: We choose our partners because of their quality and how they produce their garments. We have very specific label standards. Transparency is the most important thing to us and our customers. Our manufacturing partners need to fit into our concept, our philosophy and idea of production processes.

So this is more important than price for example.

Julia Leifert: Absolutely! And for us, sustainability is more than just using organic fabrics. It means that people are treated well and paid fairly which also enables them to do a good job. We have visited our business partners, we know how they produce, where the garments come from and how the employees are treated.

Victor Koshevsky: I can confirm that this is a huge trend. The market demands more transparency, as sustainable production becomes more important. We have been visited by several designers looking at our plants and asking very specific questions like: How do you dispose of your waste, do you recycle, where does your water come from or what is your social responsibility? They were even speaking with our seamstresses and questioning people working there, proving sustainability is crucial today. You either adapt or you will lose business.

Victor, your company also adapted to another market demand: You do not only take orders for mid-size and large scale productions, but also from these with smaller order. This is very unusual. It seems to be one of the hardest challenges for design startups to find manufacturers that are willing to produce small runs. What is it like to work with small scale brands and what are the challenges and opportunities?

Victor Koshevsky: It was actually a huge challenge. When we participated in the last Berlin Poland networking event, we decided to offer production without minimum order quantities. This opens a big market.On the other hand, you have to reinvent your business to make it work. It’s extremely time consuming in terms of labor. Young designers and start-up companies don’t have much experience, so you have to consult with them. It is more about selling services than a matter of manufacturing capabilities. At least the management crew and customer care team need to be able to speak English and German to communicate with the clients. That is the biggest challenge: to find people speaking all three languages and having at least some experiences in the textile industry. Another challenge we had to face was how to select clients and organize and schedule projects. After the Berlin-Poland event the manufacturing demand was overwhelming and exceeded our capacities.

›We won’t be producing simply to fill orders for stock, which eventually will be partially sold. We will only produce what we are able to actually sell.‹

Marita Jablonski

Let's talk about the future of the fashion industry. Looking at digitization, automatization, omni-channel distribution as well as a re-defined focus on customer and brand experiences, we see a lot of transformation in the industry. From your perspective, what are the biggest opportunities?

Victor Koshevsky: For me, there are two main points: The omni-channel-distribution, which is most certainly the future of the garment industry — not just in Berlin, but generally all over the world. Furthermore bespoke garments sold online is another significant trend, especially in the U.S.. I think it will dominate the online market in a few years.

Marita Jablonski: I think manufacturing is going to change. We won't be producing simply to fill orders for stock, which eventually will be partially sold. We will only produce what we are able to sell. From an ecological point of view this makes a lot of sense. We already have the machinery and pattern software, but the workflow process connecting everything is still not there. It will take some time. We will see an increase of smaller batch orders first and then of more and more individual, customized products.

Greg, do you agree with these future forecasts?

Grzegorz Słupianek: To some extent. I don't believe that we will have the technology to replace analog tailoring soon. But mass customization is definitely the future. With all the digital sales channels, we already have the resources we need. Designers and labels can learn more about their customers, analyze their data and use it to target them better. Selling online also offers a bigger profit margin for fashion labels and designers compared to the wholesale distribution chain.

Julia, your label is an emerging brand in the premium sector. How does it effect your work, if more and more manufacturers are open to work with small scale brands? Would it help you, if you could produce lower quantities and maybe also cut out the middleman and sell directly to your customers?

Julia Leifert: Definitely. It’s important to us to have partners who can produce small quantities in short term conditions, because we don’t have the financial resources to have a large stock. We only sell online at this time and don’t have a lot of warehousing space.

›The market has changed tremendously. It’s more about working together rather than competing.‹

Victor Koshevsky

Thanks to trends like mass customization, sustainability and fair production, we see a revival of manufacturing in Central Europe. What kind of support would help you to scale and professionalize your cross-border collaborations?

Julia Leifert: For us it is great having the opportunity to meet once a year at a platform, panel or networking event where people can share their experiences.

Grzegorz Słupianek: Matchmaking events like the Berlin-Poland B2B-program are a great opportunity to meet potential cross-border business partners. For example at the last fair we made eight contacts with whom we did business with later.

Victor Koshevsky: I would even go a step further. My suggestion is to build a network of cooperating manufacturers in Poland and Eastern Europe. My team receives a lot of requests for specialty products we are not able to manufacture in-house and sometimes we even struggle to find someone who can work in our place. A network for helping each other would ease this process. I also see a demand for having meetings on a regular basis with manufacturers, designers and labels to exchange experiences. The market has changed tremendously. It’s more about working together rather than competing.

Grzegorz Słupianek: I also don’t believe that we’re living in a limited economy where there is not enough for everybody. I truly think that the more we help each other, the more we gain. Everybody profits! Seeing each other once a year, creating a platform of competences, being synergistically stronger than each of us on our own is a great idea.

Marita Jablonski: I totally agree. It's our daily business to share knowledge and we profit from suppliers, designers and manufacturers sharing their experiences and expertise with us. Everybody wins.

The next B2B networking event will take place at Kunstgewerbemuseum on October 26 and 27. Fashion brands and designers from Berlin are still invited to take part. The registration is open till October 15: berlinpoland.eu

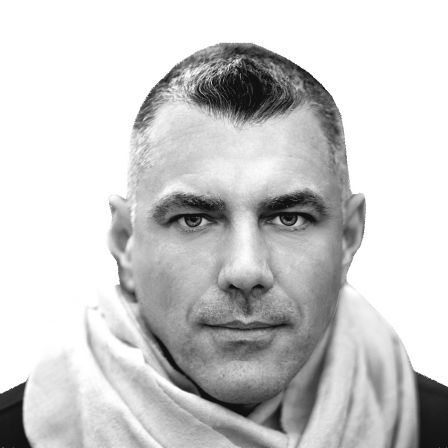

Victor Koshevsky

Director of Dynalian and Poge Industries

Victor Koshevsky is the director of Dynalian, a New York-based full service contractor for the garment industry and Poge Industries, a Poland-based garment manufacturer and service company. The family-run company was founded by Victor Koshevky's uncle in the late 80s. It offers a wide range of services: from small to large scale production to omnichannel distribution and sales.

Julia Leifert

CEO & Founder of Philomena Zanetti

Julia Leifert is the CEO and founder of Philomena Zanetti, a Berlin-based sustainable luxury brand for women's wear. The young brand presented their collections at Mercedes Benz fashion week Berlin for three consecutive seasons in and featured their work in New York and Paris. Recently, Philomena Zanetti won the German Fashion Council Price in sustainability.

Grzegorz Słupianek

CEO & Production Manager of Art Dress

Grzegorz Słupianek runs Art Dress, a fashion agency and studio. The company has been offering fashion manufacturing services for brands from all over the world for nearly 30 years. From making samples and patterns to consulting and producing garments. Since Art Dress is a family business, Grzegorz Słupianek has worked at each level of the company starting at the bottom of the company when he was a kid.

Marita Jablonski

CEO of Good Garment Collective

Marita Jablonski is the CEO of Good Garment Collective, a Berlin-based full service garment development and production agency for fashion start-ups as well as established brands. They offer services within the product development stage and production of garments such as fabric sourcing, sample making, digitizing patterns or production management. They consult with clients within the production process and help them to find manufacturers.